Welcome to the “Ultimate Resistance Testing Guide,” where we’ll dive into the complexities of resistance testing with a streamlined process.

Resistance tests differ from voltage and current tests; they typically involve turning off the equipment and disconnecting its components to guarantee precise measurements. Come along as we examine the several types of resistance tests and discuss the fundamentals of this essential area of electrical testing.

Understanding resistance testing is essential in ensuring the reliability of components within electrical circuits. When dealing with components that exhibit pure resistance, the process is relatively straightforward. The resistance reading should remain consistent across both AC and DC circuits. However, the complexity arises with components used in AC circuits, where impedance plays a significant role in circuit performance. Components containing coils or capacitances introduce AC impedance, impacting overall circuit operation. While ohmmeters are effective in measuring DC or pure resistance, the introduction of AC component testers becomes crucial for accurately assessing impedance in these scenarios.

To grasp the full spectrum of resistance testing capabilities, let’s dive deeper into the different types of tests:

Wire Continuity Tests

Many electrical troubles are caused by breaks, or opens, in wire continuity, as well as increased resistance in a connection. Continuity testing is merely a test to show that there are no complete breaks in a wire, whereas resistance testing generally measures for a more specific reading in ohms. Since reading is not always necessary in a continuity test, many continuity testers sound audible to notify the user when continuity exists, while an analog or digital meter would show zero or very low resistance.

Testing the continuity of a wire requires connections to both ends of that wire. With a short wire, this is not difficult, but with a long wire, where one end might not be accessible, that end might have to be tied to another return wire so that the continuity of both wires can be tested in series.

Wire Resistance Tests

While continuity tests serve as valuable general indicators in many scenarios, they may not always reveal the full picture, especially when dealing with intricate setups like stranded cables. In such cases, even though continuity may be present, a hidden issue could appear: one or more broken strands within the wire leading to higher-than-expected resistance. Furthermore, a faulty connection might permit continuity while yielding an unexpectedly high resistance reading. This is where resistance tests step in, offering a more nuanced approach. Similar in execution to continuity tests, resistance tests provide the additional benefit of obtaining ohm readings on a meter, allowing for a more precise assessment of the wire’s condition. For longer wire lengths, understanding the normal resistance of the wire over its length becomes imperative, ensuring accurate diagnostics and maintenance protocols.

Infrared Tests

In the realm of electrical testing, the challenges mount when it comes to long-line testing and obscured wiring. Traditional continuity and resistance tests often fall short in these scenarios, leaving critical issues undetected. However, the advent of infrared scanners offers a game-changing solution. These sophisticated tools enable users to identify high resistance effects even while equipment is operational, revolutionizing diagnostic capabilities.

High resistance within a circuit poses significant risks, leading to power dissipation and heat generation. Enter infrared testers, also known as thermal testers, which provide a non-invasive means of detecting such anomalies. The process is meticulous yet straightforward: users aim the tester first at a known normal temperature target to establish an ambient reference reading, then proceed to scan various suspected targets within the circuit, typically connections. Some units even offer audible cues or visual displays, such as lights, to indicate the severity of detected heat. Additionally, advanced models provide precise temperature readings, empowering users with comprehensive insights into the health of their electrical systems.

Circuit Tracing

Short Tests

When an electrical line experiences a short circuit, it often results from wear and abrasion of insulation, exposing the bare conductor and facilitating contact with grounded metal or other damaged wires. This can occur especially if there’s damage to the insulation of a hotline, as in nonmetallic sheathed cable where the grounded wire is bare, or in BX cable or conduit where the metal sheathing is grounded.

Detecting shorts parallels the process of conducting continuity tests. If a short exists between a hot wire and the ground, an ohmmeter will indicate continuity along that line, through the short, and back through the ground (with the power disconnected). However, pinpointing the exact location of the short presents a challenge. For longer lines, comparing the resistance reading of the wire with its normal ohms-per-1000 feet serves as a guide to locating the short. Alternatively, for shorter lines, the signal tracer test offers a solution. As the receiver is moved along and near the hotline, it detects signal reception before reaching the short, but the reception fades out as the short is passed, aiding in locating the fault.

Open Tests

Open tests are a variation of continuity tests aimed at identifying open circuits within a circuitry setup. In these tests, the user seeks to confirm the presence of an uninterrupted circuit path. A reading of continuity, indicating little to no resistance, confirms the integrity of the circuit, while a reading of high or infinite resistance signals the presence of an open circuit.

When it comes to testing a power switch, a similar approach can be adopted using a voltmeter or an ohmmeter (with the power disconnected for safety). By connecting the ohmmeter across the switch terminals, users can assess its continuity. A reading of zero ohms or continuity, when the switch is turned on, signifies its proper functioning. Conversely, a reading of infinite or very high resistance indicates a faulty switch, suggesting an open circuit within the switch mechanism.

Hi-pot Testing

Hi-pot testing is more dependable because it applies kilovolt power to come close to replicating real operations. Often, up to over 60 kilovolts (kV) is used depending on the cable. An ac hi-pot more closely replicates real operation, but dc hi-pots are simpler to utilize in the field. A high surge current occurs when the test starts since the long line acts as a charging capacitor, but this settles down to a leakage current. The hi-pot test voltage is usually stepped up in 5- to 10-kV steps, and leakage current is noted at every step to make sure it is within appropriate limits. If the insulation is defective, it will break down under the kilovolt pressure to allow excessive current to flow. Usually, the length of the line is “walked” to inspect it before testing is done. Weather, moisture, and wind affect hi-pot results, so it should be performed on a calm, low-humidity day. The hi-pot test voltages and reading results should be within the wire manufacturer’s specifications to prevent cable damage.

A robust ground connection is paramount for ensuring both personal safety and the protection of equipment in electrical systems. In any service entrance power setup, the center tap of the power is designated as the neutral line and is bonded to the ground using a metal stake or connected to existing metal equipment at ground potential, such as metal plumbing pipes—particularly the main water line from the exterior.

Within the entrance junction box, the ground and neutral terminal bus bars serve as crucial junction points for various components, including the neutral entrance line, system ground wire, and the neutral (white) and ground (bare) wires of every distribution line. It’s imperative that each metal conduit, BX cable, box, appliance, and tool cabinet or cover maintains ground potential (0 V) to prevent the risk of electrical shock upon contact.

Modern wiring receptacles and plugs are designed to automatically provide grounding at outlets, effectively neutralizing any potential hazards. Notably, the center screw on the outlet plate of such outlets is also grounded. In cases where equipment lacks self-grounding capabilities through its plug, its metal cover or cabinet should be connected to the ground via a dedicated wire.

To ensure the integrity of the ground connection, it’s essential to follow proper testing procedures. Before proceeding, ensure that the mainline power is switched off for safety. Utilizing an ohmmeter, test the resistance from a metal plumbing pipe to all grounded points. A reading of zero ohms on the ohmmeter confirms a solid ground connection, providing assurance of a safe electrical environment.

How Apex Waves Can Help

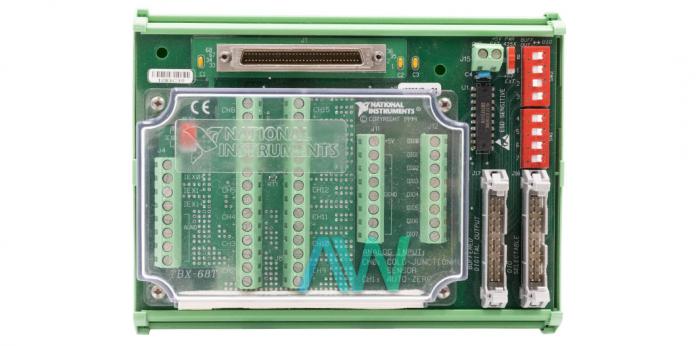

Apex Waves provides cutting-edge solutions that can greatly improve testing procedures and guarantee the best possible functioning of crucial components.

Our company offers a range of highly valuable tools and equipment designed to handle unique issues found in these industries, including wire resistance assessments, wire continuity tests, and more.

To learn more about Apex Waves, our products, and selling your surplus parts, get in touch with us today!