Calibration Services

NIST Accredited or Basic In-House Calibrations

Ensure Reliability With Professional Calibration Services

Calibration is essential for ensuring the accuracy of test equipment. Over time, factors such as wear and tear, environmental conditions, and component aging can cause the measurements of testing instruments to drift. Calibration helps to identify these gradual changes and corrects them, bringing the instrumentation back to its original and most accurate state.

The calibration process is all about attention to detail. It involves following established procedures with specialized calibration equipment, and adjusting the frequency depending on the instrument’s usage, stability, and environmental conditions.

It is recommended to calibrate most devices either annually or every two years in order to maintain accuracy.

OR

Basic In-House Calibration

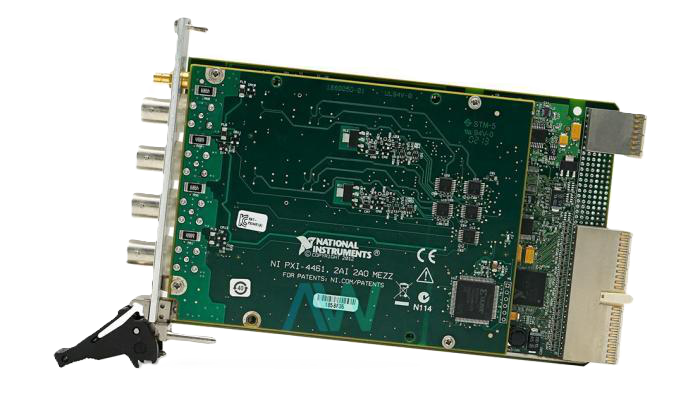

- Basic (unaccredited) in-house calibration for parts upon request when ordered.

- Calibrated to manufacturer specifications prior to being shipped.

- Our entire stock of NI parts is calibrated prior to being put on the shelves, eliminating calibration wait times after purchasing.

Why is Calibration Important?

There are many vital benefits to regular calibration. Not only will your test equipment have a higher accuracy, but small faults can be identified and corrected before leading to costly repairs or equipment failure, resulting in a longer product lifespan.

With regular calibration, industries can maintain compliance with standards and regulations and make informed decisions to enhance product quality. Professional calibration services are an essential aspect of any quality assurance program, contributing to cost savings, efficiency improvements, and extended equipment lifespan.