Switches are the first basic building block of a successful electronic device. Since they have the power to either complete or disrupt an electrical circuit, control is impossible to achieve without them. Switches are fundamentally binary devices (they can only be either entirely on or completely off), but how do they work? While there are many different types of switches to discuss, this post will take a look at some of the most common types of manual hand switches and how they function.

Common Hand Switch Types

Manual switches designed to be operated by humans are known as hand switches. These include:

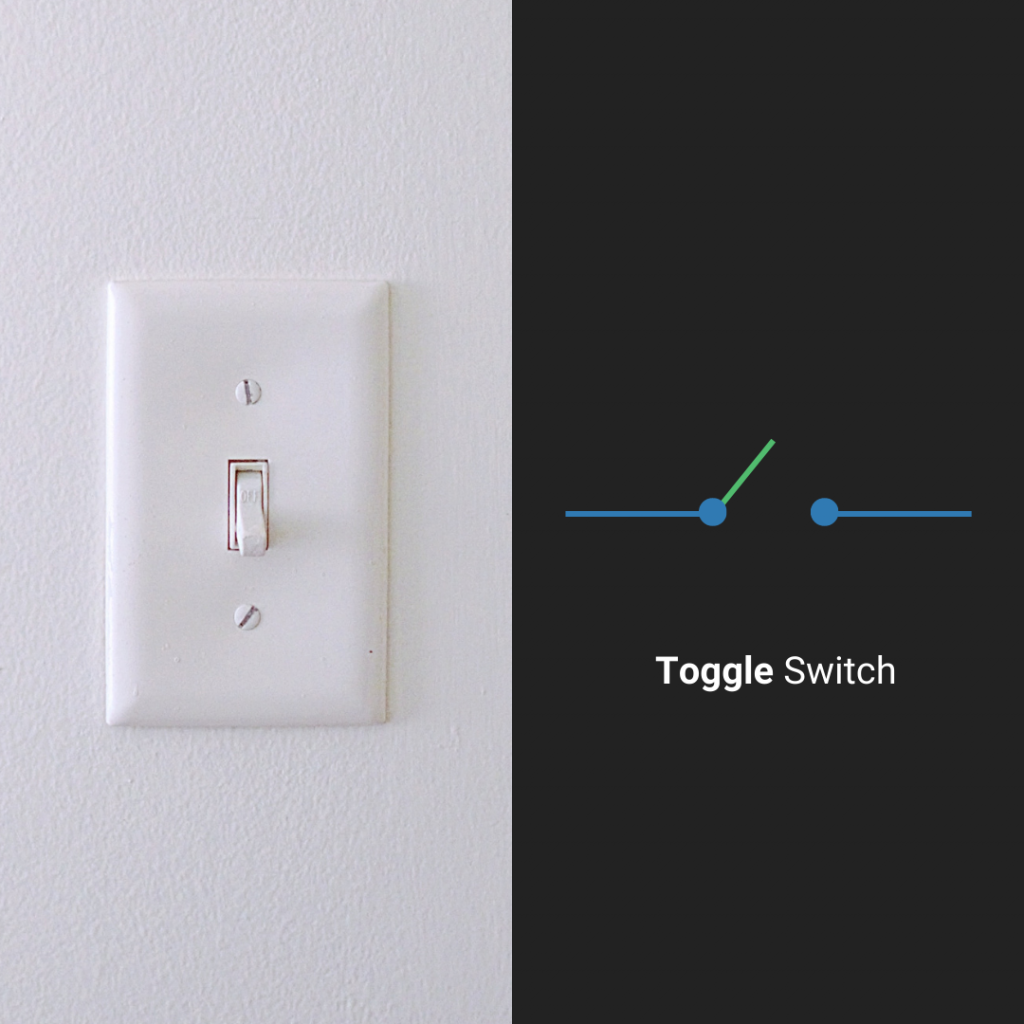

Toggle Switches

Toggle switches are operated by a lever that is tilted in one of two or more places: a common example being a household light switch. By moving the lever, an electrical circuit is either opened or closed, and the position of the lever provides a visual cue as to the condition of the circuit. The lever of most toggle switches will stay are rest in any position, but others contain internal spring mechanisms that restore the lever to a predetermined usual position, enabling what is known as “momentary” functioning.

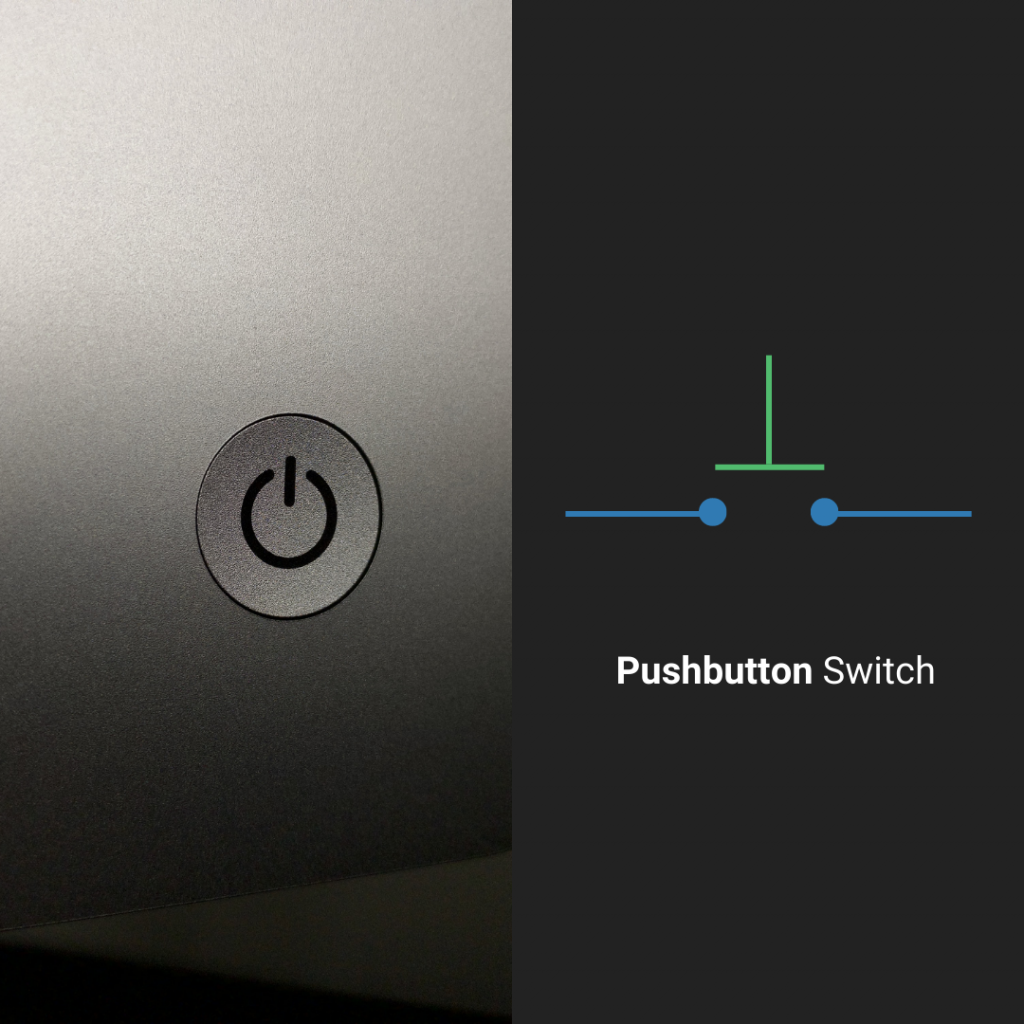

Pushbutton Switches

Pushbutton switches are the type of switch most frequently utilized by industrial control panels. They are two-position devices, operated by pressing and releasing a button that most often contains an internal spring mechanism that returns the button to its “unpressed,” state. (Some pushbutton switches are designed to stay in the “pressed” state until pushed again). With each button press, certain pushbutton switches will latch alternately off and on.

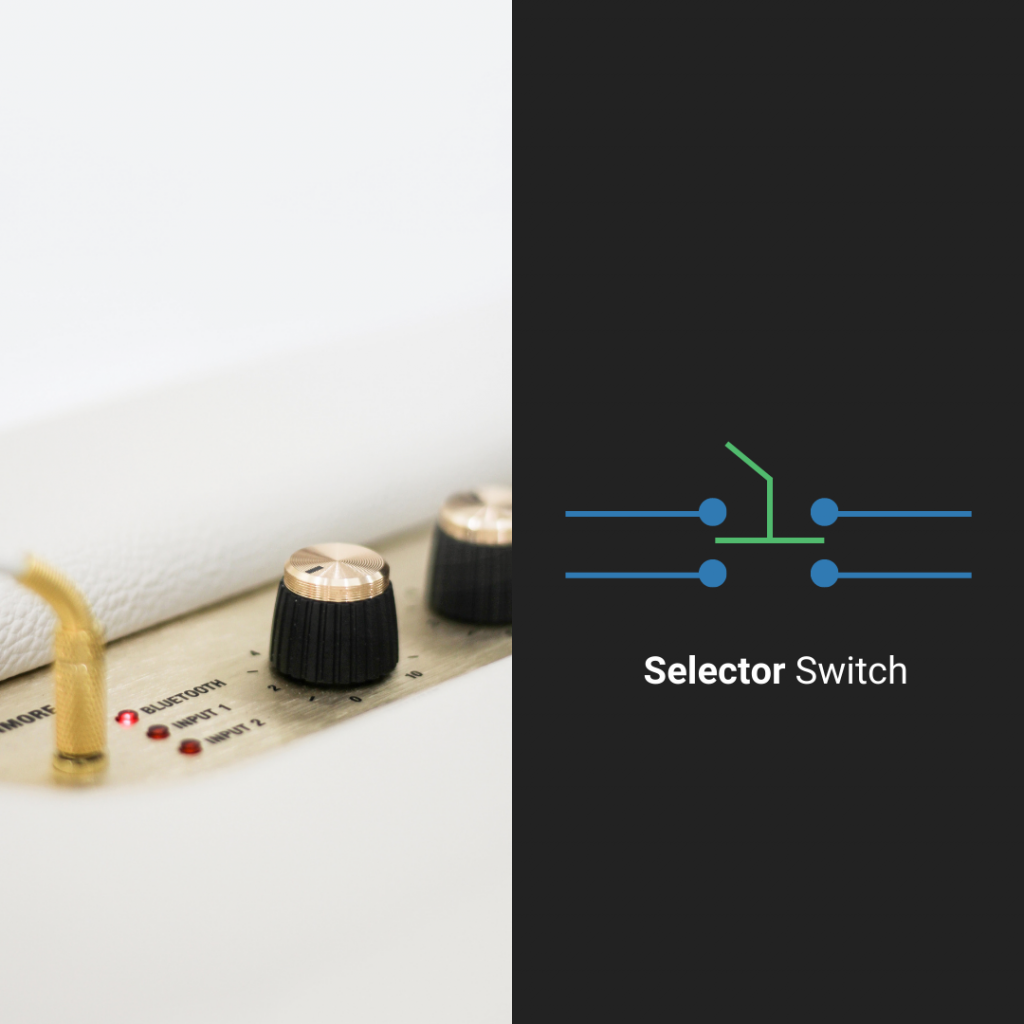

Selector Switches

Selector switches use some form of rotary knob to move between two or more locations. Similarly to toggle switches, selector switches can either be left in one position or can include spring-loaded return mechanisms.

Joystick Switches

A joystick switch is made of a lever with many motion axes that can be freely moved. Movement depends on the way in which the lever is pushed, which causes one or more switch contact mechanisms to be triggered.

“Poles” and “Throws”

The function of a switch is determined by the amount of poles and throws it has. In this context, “poles” refers to the Individual circuits that the switch comes in contact with and controls, whiles “throws” refers to the specific switch settings. For example, a switch with the settings of “high” and “low” is referred to as a “double-throw” switch. Switch types are sometimes shortened, so a “single-pole, double-throw” switch is also known as an “SPDT” switch. These names are important as they immediately indicate the number of poles and throws, providing a clear description of the switch’s purpose.

In general, the type of switch ideal for the job will be determined by the particular application. The form factor of the switch must be chosen carefully because of the various goals, functions, and physical considerations.

Designs of Switch Contacts

Any device that allows two conductors to come into regulated contact with one another can be used to create a switch. Good switch design, however, must be robust and trustworthy and prevent the danger of electric shock for the user.

Contacts are the conductive components that form or sever the electrical connections in switches. The conductivity characteristics of silver or silver-cadmium alloy contacts are often not considerably impacted by surface corrosion or oxidation. Regardless of the metal used, a mechanism ensures even contact between the switch contacts for optimal dependability and little resistance.

One drawback of standard switch contacts in industrial applications is exposure to the environment. While this would not be an issue in a clean control room, most industrial settings risk contaminants in the air such as chemical corrosives which can hasten the deterioration and failure of contacts.

Another important consideration when designing switches is the recognized standards for the environmental conditions that a switch’s housing can resist set by the NEMA (National Electrical Manufacturers Association) enclosure rating and the Ingress Protection (IP) rating.

Additional Information: