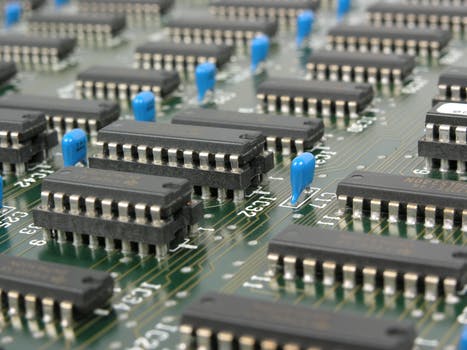

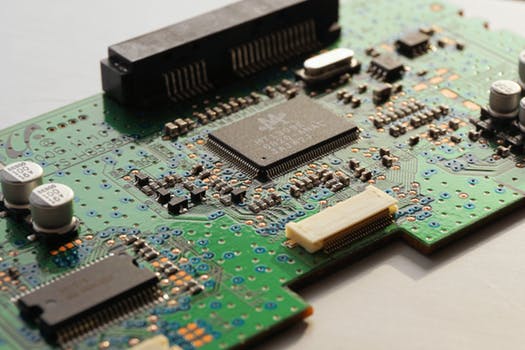

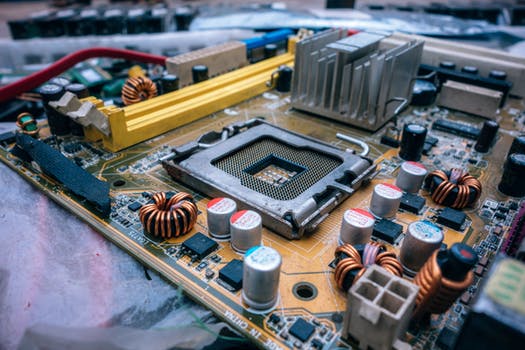

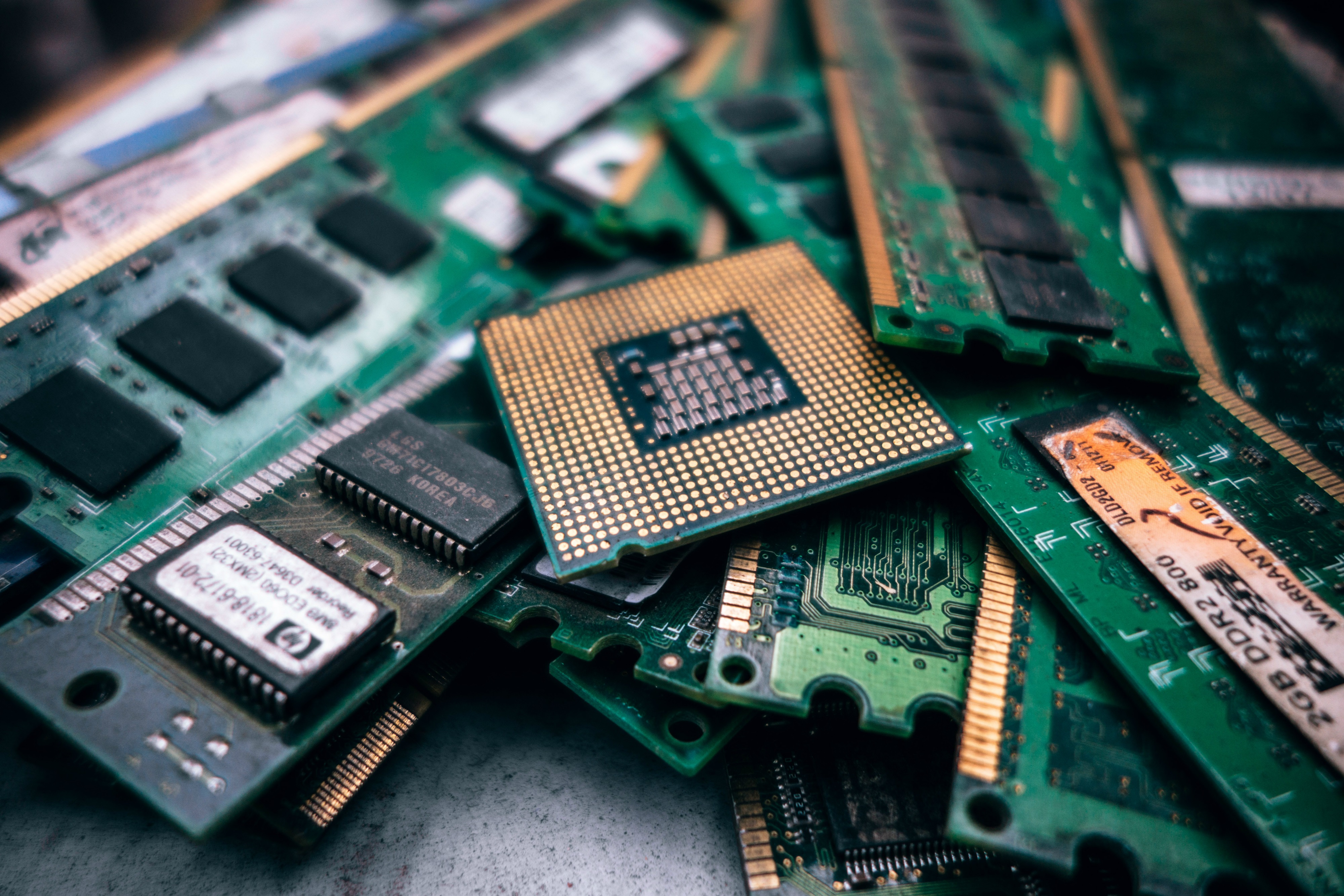

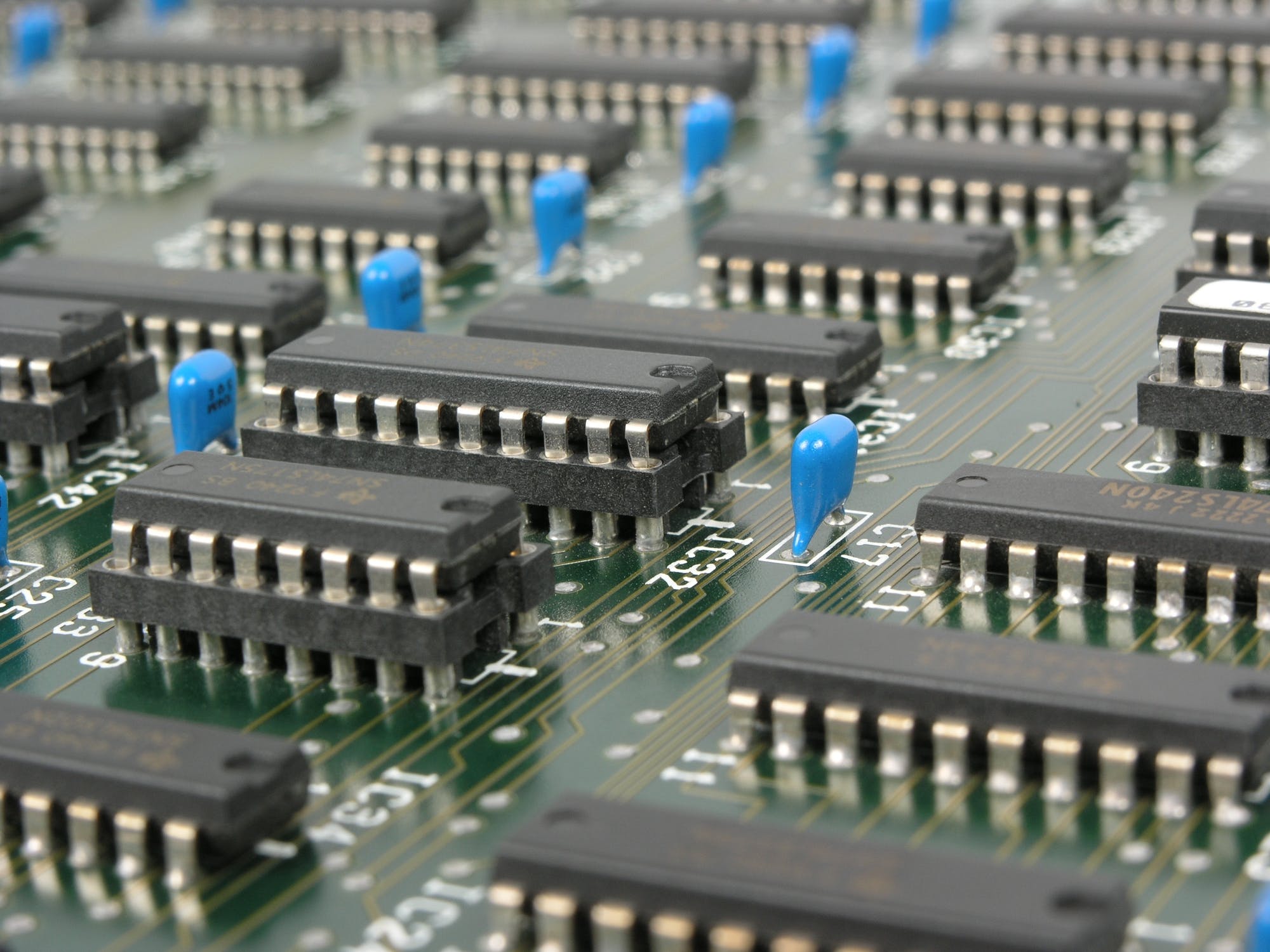

In the ever-changing field of electronic instrumentation, practicality and precision come together to show the paths taken by circuitry and systems. Input networks, amplifiers, op-amps, pulse generators, and oscillators—all fundamental components defining the essence of contemporary electronics—will be covered in this article.

Continue reading “All About Digital Circuits”