Ever since the first generators, harmonics have been a part of power systems. However, we now live in an era of power that is defined by non-linear loads. Equipment for powering computers, electronic ballasts, and VFDs are among the electronic power supplies that are used now more than ever. Unchecked harmonic distortion in these electrical equipment systems can result in damage and hazards such as overheating. Not only does this affect power quality, but it can become costly to fix. The question then becomes: do you know how to correctly measure the waveforms of your equipment while taking harmonic distortion into account?

What is Harmonic Distortion?

Harmonic distortion was not a noticeable issue for many years. Machinery such as household appliances are classified as linear loads, as they draw in electrical currents that produce perfectly sinusoidal ac waveforms. Around the 1960s, the amount of equipment in heavy industry and commercial settings that are operated by electronic controllers grew exponentially. These facilities often draw power currents from non-linear loads, resulting in distortions in the sine waves. Harmonics refers to the composite of multiple waveforms. Thus, harmonic distortion refers to the level at which these waveforms from non-linear power sources are misshapen and not perfectly sinusoidal.

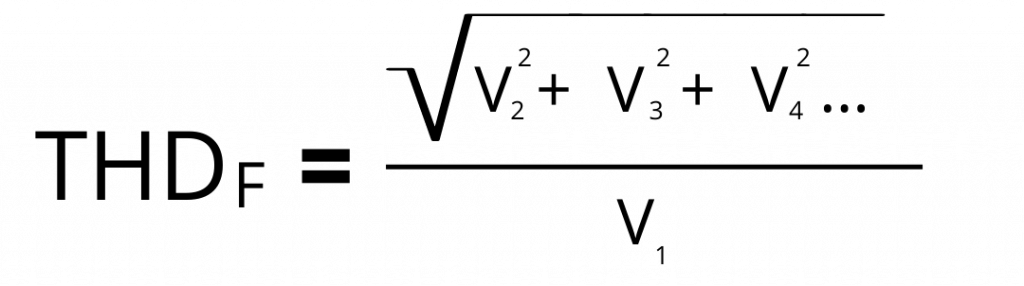

It is clear that because of harmonic distortion, it is now more important to monitor a facility’s power system’s overall condition. Integer multiples of the waveform’s fundamental frequency make up the harmonic frequencies. For instance, the second, third, fourth, and fifth harmonic components of a 60 Hz fundamental waveform will be at 120 Hz, 180 Hz, 240 Hz, and 300 Hz, respectively. The total harmonic distortion (or, sum of all the harmonic components within the waveform compared to the “fundamental component” of the signal), can be found using the formula:

Where “THD” refers to the total harmonic distortion, and “Vₙ” refers to the “nth” harmonic’s RMS (root mean squared) value.

Issues Measuring Distortion

A common method used by ac meters for many years to show the RMS value of a current is the “average responding rms indicating” technique. This approach uses an ac waveform that is mathematically calculated using RMS to provide a value that is similar to the dc level that would result in the same heating value as the ac current being measured- all without the use of pricey and sensitive laboratory equipment. In essence, the rectified signal’s average value is calculated, multiplied by a fixed factor, and the result is the rms value.

The issue with this method is that the waveform being studied needs to be a perfect sine wave to be reliable, and there is no assurance that the ac voltage of a wall outlet will create a flawless sine wave. In a worst case scenario, an average responding instrument may give values that are up to 50% too low.

What is Most Accurate?

There is good news! True-rms devices provide accurate readings for all types of signals. However, there are a few key factors to keep in mind. The first is that Any ac meter’s performance is constrained by both its crest factor ratings and its bandwidth. Bandwidth describes the frequency range that the meter can accurately measure.

A commercial grade meter can manage the frequency range present in the majority of industrial or commercial power systems, if it has a bandwidth of at least 1kHz. If the object that is to be measured is within an audio or communication system, consider a larger bandwidth meter.

Crest factor describes the ratio of a signal’s peak value to its rms value. ratio of a signal is known as the crest factor. The crest factor of a sine wave is 1.414. Because of this, a meter with a crest factor rating that is higher than 1.414 would be adequate in a system with pure sine wave voltages and currents. However, harmonics raise the signals of a system to have greater peaks, which raises their crest factor. For this reason, it is beneficial to have a meter that has a whole scale crest factor value of 3 or above.

Make sure that additional factors are taken into account when assessing true-rms instruments. You will want to have a tool that can withstand ac and dc signals of at least 600V. It is also beneficial to make sure your meter / device monitors frequency, capacitance, and continuity.