The second day of NI Connect 2023 brought just as much excitement as the first. The overall theme of the conference’s second keynote was NI’s vision to support a more connected world, and it brought together guest speakers from prominent organizations such as Northeastern University, NXP, and the Battery Innovation Center. Keep reading for a recap of what was discussed in the second and final keynote of the conference!

The first and foremost speaker for the second keynote is Thomas Benjamin– CTO, EVP, and Head of Platform and Analytics R&D at NI. Benjamin welcomes the audience back by discussing the power of utilizing insight and measurements to create a more variable, remote-integrated, and automated future. Benjamin points out the importance of connectivity with medical care technology and compares the function of other electronic systems (autonomous vehicles, LIDAR, etc.) to a patient care team. He emphasizes that “organizations who embrace the possibilities of these connected systems will have a significant market advantage over those who maintain lenial, siloed product life cycles with disconnected data strategies and lack of visibility into product performance”.

Benjamin then sets up the structure for the rest of the keynote by introducing NI’s vision for the future of testing: an autonomous hyper-automated system of systems. This system is comprised of 4 interconnected but separate core areas: integrated design and test, automated data insights, smart connected test systems, and connected user workflows.

Area of Focus: Integrated Design and Test

Core Elements: The use of multi-dimensional digital twins, using trusted sources of truth, and system-level testing.

Guest Speakers: Dr. Kaushik Chowdhury, Northeastern University, and Dr. Amr Haj-Omar, NI.

The first area of this hyper-automated system of systems that is addressed in the keynote is Integrated Design and Test. To discuss this, Thomas Benjamin welcomes Dr. Kaushik Chowdhury (professor of electrical and computer engineering at Northeastern University), and Dr. Amr Haj-Omar (Business Development Manager and Wireless Communications Research at NI). They discuss the importance of multimodal data from the multiverse in regard to the wireless applications of machine learning. The term “multimodal data” refers to the use of digital twins for both real cameras and real LIDAR.

Dr. Haj-Omar and Dr. Chowdhury partnered together to release an open-source code that enables engineers to collect and manage wireless datasets. This code is known as the RF Data Factory, and it is freely available on GitHub.

As products get more complex, the design process for testing has to shift in response. the design process. Dr. Chowdhury mentions The Colosseum, a massive RF emulator that began as a project under DARPA and is now overseen by Northeastern University. NI is now working on scaling the capabilities of the Colosseum into small, individual chassis.

Area of Focus: Automated Data Insights

Core Elements: A foundational data platform, product-centric analytics, and insights into actions.

Guest Speaker: Shelley Gretlein, NI

Thomas Benjamin introduces this area of focus by emphasizing NI’s belief that “test and measurement data is the most underused asset within an organization”. He invites the VP of Software and Offering (Portfolio Business Unit) for NI, Shelley Gretlein, to discuss the importance of measurements.

Benjamin brings up that a standard product feedback loop is an easy concept, but it is not easy to implement in practice. While many companies have siloed data sources, a foundational data platform breaks silos down using data. The platform associates the input variables with the product outcomes that the user wants. In this case, it is the feedback loop that unlocks the effectiveness of automation.

Gretlein goes on to discuss how the approach and software from NI create the perfect infrastructure for machine learning. Machine learning can become a competitive advantage by taking the same foundational data model and using it as the validation and training dataset. In this way, product-centric analytics and the supervised machine learning model can be connected to product outcomes, and the model can be embedded into multiple other processes.

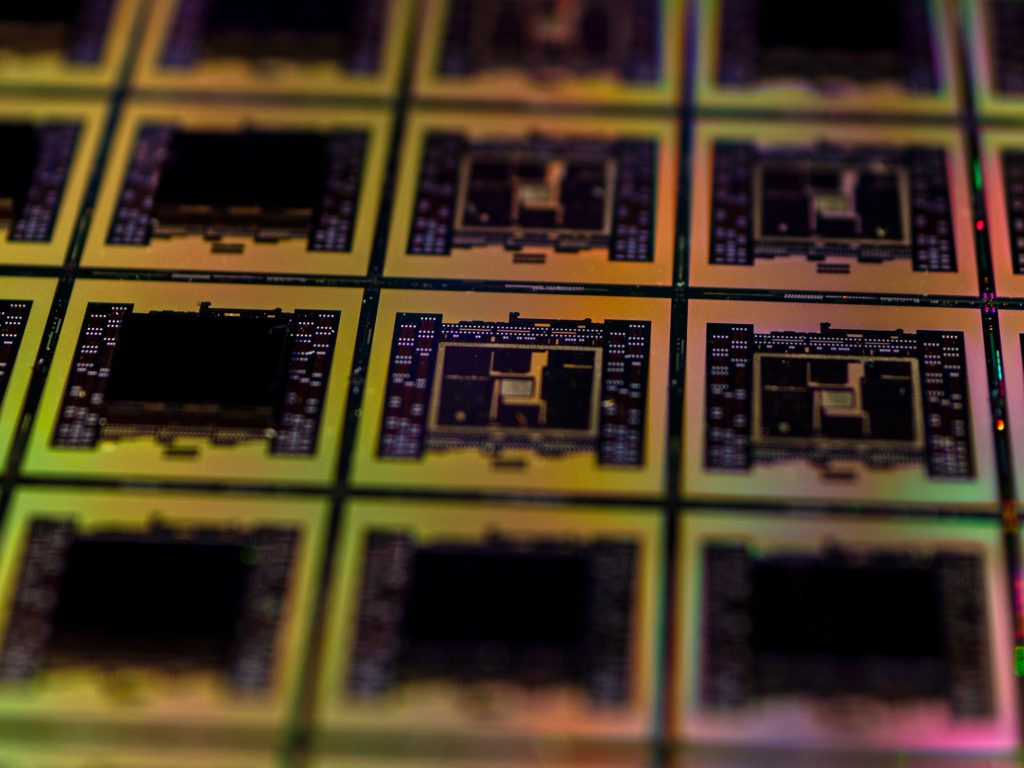

The new wafer classification tool from the Renesas company uses machine learning to automatically sort wafers while still allowing for manual edits. Similarly, NI’s OptimalPlus GO semiconductor test and assembly wafer system gathers, cleans, and analyzes data from various data sources to prevent faulty products from going to market.

Area of Focus: Smart Connected Test Systems

Core Elements: new and advanced measurements, streamlined asset management, and scalable computations.

Guest Speakers: Eli Kerry, NI, and Ben Wrightsman, Battery Innovation Center

Chief Offering Manager of EV Battery Solutions for NI, Eli Kerry, joins Thomas Benjamin on stage along with CEO of the Battery Innovation Center, Ben Wrightsman. They discuss the importance of smart connect test systems in terms of EV batteries, noting that instrumentation systems are making a switch from being PC-centric to being centered on cloud tech.

It is discussed how it can take several days to several weeks to build a battery, and those multiple required steps allow for multiple opportunities for issues to arise. By decreasing manufacturing time, the batteries experience fewer points of failure.

To achieve this, it is necessary to introduce testing throughout the manufacturing process- not solely at the end of the line. It is here that the new NI Sub-THz Reference Architecture comes into play. A requirement for 6G wireless systems, the architecture features 4 GHz of bandwidth and 173 GHz of frequency coverage, all with sustained data streaming in real-time.

Area of Focus: Connected User Workflows

Core Elements: seamless workflow transitions, ready-to-run measurements, and a central shared library.

Guest Speakers: Darcy Dement, Chris Cifra, and Alejandro Barreto, NI.

Darcy Dement, VP of Product Management and UX for NI, joins Benjamin on stage along with two engineers from NXP, Wolfgang and Eric.

They discuss the importance of connecting workflows using programs such as SystemLink, LabVIEW, TestStand, and InstrumentStudio. At NXP, they noticed that each team had to develop their software infrastructure from the ground up. This was distracting from testing the product by putting more focus on building the framework. To address this, the teams at NXP began a pilot project that allows teams to develop test codes in the programming language of their choice and share it.

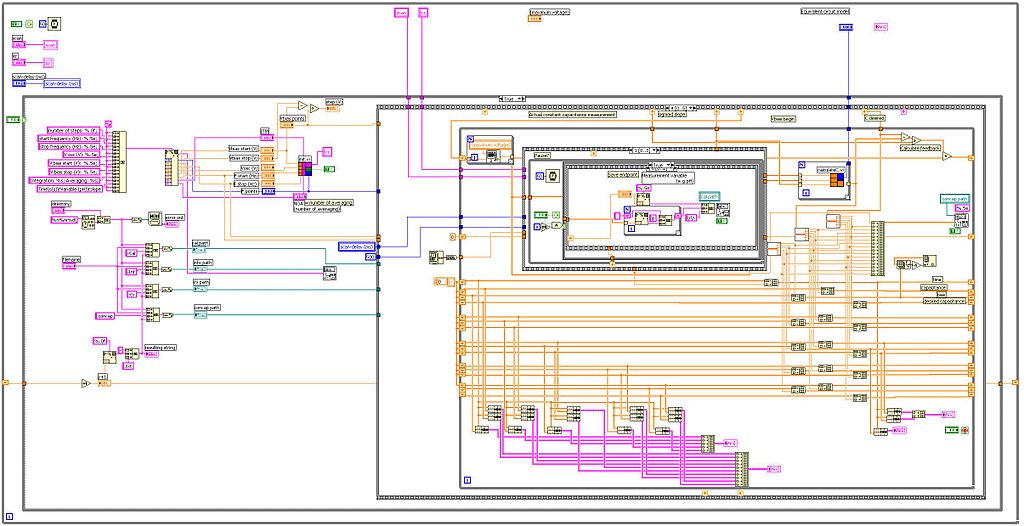

They go into more detail about the new Measurementlink software, noting its ability to debug interactive automation and minimize time-to-test. Measurementlink makes code accessible as reusable “ready-to-run” measurement blocks that can run automatically in InstrumentStudio or in an automated sequence in TestStand with no additional coding. “Ready-to-run” refers to the storing of compiled, deployable versions of measurement software, which are made accessible to the entire test team without having to know the underlying sources.

The final demonstration of the keynote is perhaps the biggest moment of the day. It is here that NI unveils NIGEL AI, their new AI assistant that can help code in LabVIEW. While ChatGPT can write blogs or emails, NIGEL is tuned for test and measurement and has the ability to actually control physical hardware and connect to apps.

The NIGEL AI was built on top of GPT 4.0, trained on NI hardware and software, and then connected to the LabVIEW API and taught about DAQMX. Unlike any other AI currently in use, NIGEL is capable of generating graphical code– allowing programmers to solve problems faster.

Following a demonstration of NIGEL taking a task from spec to test in roughly 5 minutes, the keynote concludes on a hopeful note. While AI will soon change day-to-day workloads, NI Connect 2023 has shown that NI tech is more than prepared for the challenge.