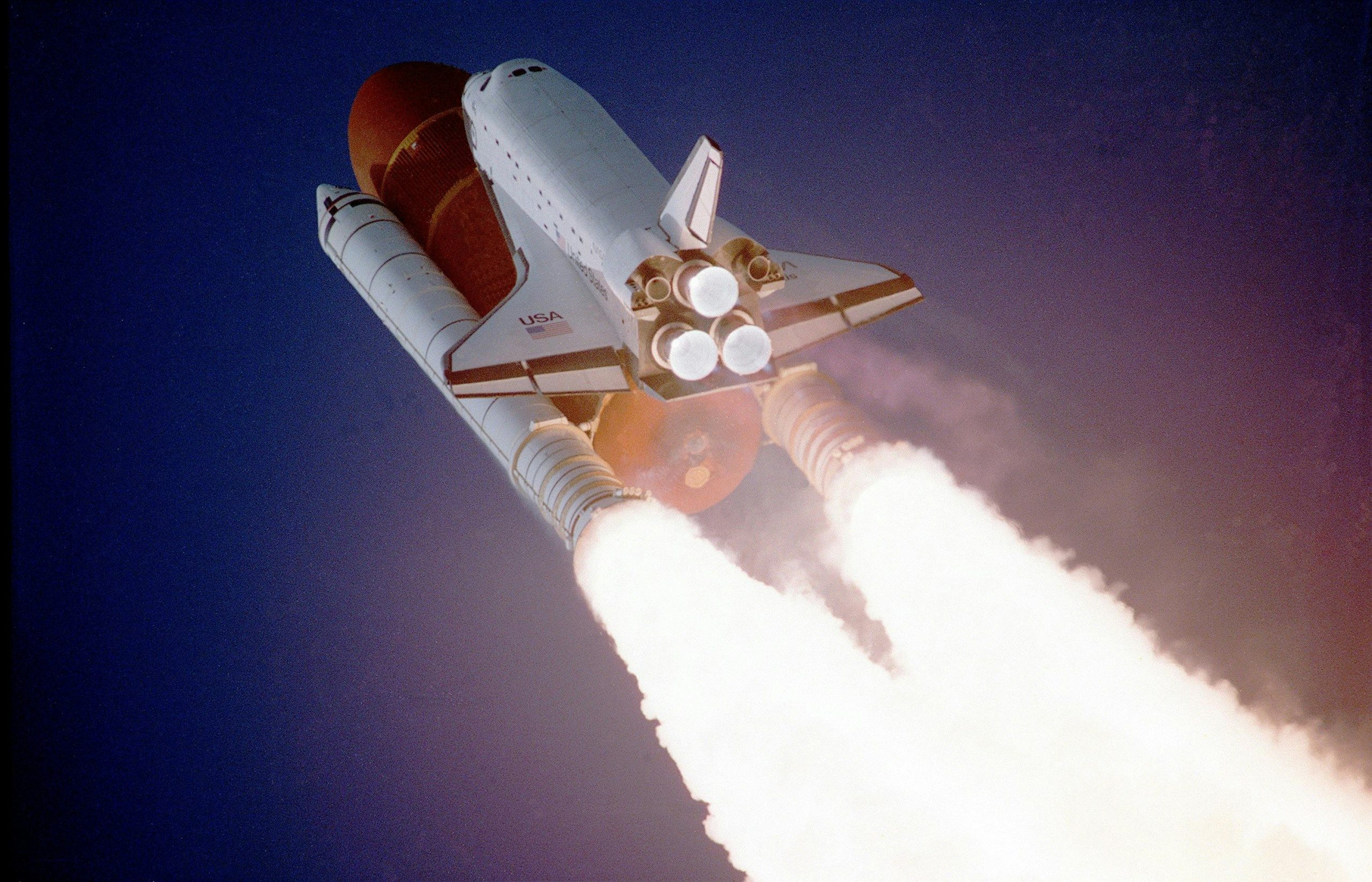

In the booming field of space exploration, accuracy and dependability are critical. Each space mission is an amalgam of state-of-the-art technology, painstaking preparation, and unflinching resolve. The arduous process of testing the launch vehicle, which involves examining each component and putting each system through its paces to ensure a successful flight beyond Earth’s atmosphere, is at the center of this endeavor.

Firefly Aerospace and Tech180 have set out on a revolutionary path, utilizing the capabilities of NI (National Instruments) technology to completely change the testing and preparation of launch vehicles for their space travels. Their partnership represents an advancement in the rapidly changing field of space exploration, offering everything from improved precision and efficient processes to affordable solutions and more.

The Rise of NI Technology in Launch Vehicle Testing

Firefly Aerospace has progressively become more involved in the aerospace industry as its commitment to pushing boundaries and creating new technologies has persisted. As the demands of launch vehicle testing become increasingly complex, Firefly recognizes that increasingly sophisticated solutions are required in order to maximize reliability and expedite processes.

As the push for more aggressive space travel continues, company collaborations are becoming more frequent to discover innovations and improve the efficacy of spacecraft manufacturing. NI technology’s suite of equipment provides superior capabilities in data acquisition, control systems, and test automation. Its significance in aerospace testing lies in its ability to provide real-time insights, improve accuracy, and accelerate testing timelines. By taking advantage of NI technology, they are able to achieve greater precision in data collection, ensuring that every aspect of their vehicles is thoroughly evaluated before takeoff.

In addition, NI’s flexible and scalable platform allows Firely to adapt to evolving testing requirements with ease, permitting greater efficiency and productivity in its operations. In essence, the collaboration with NI technology has greatly helped Firefly Aerospace succeed in its missions and elevates both the quality and reliability of its launch vehicles.

Tech180’s Role in Advancing Aerospace Testing Through NI Technology Integration

With a plethora of experience in designing and testing solutions, Tech180 has grown to be a powerful force in the aerospace sector. The company made a name for itself as a go-to partner for similar businesses searching for innovative solutions in aerospace testing by emphasizing efficiency and innovation. Their successful history and dedication to high-quality products have guided them toward several partnerships with leading organizations, including Firefly.

The collaboration between Tech180 and Firefly Aerospace in adopting NI technology represents a strategic alliance aimed at pushing the boundaries of aerospace testing. By leveraging NI’s advanced solutions, Tech180 enhances its ability to deliver comprehensive testing services that meet the rigorous demands of space exploration. Tech180’s commitment to keeping at the forefront of technical innovations is demonstrated by this agreement, which helps ensure that it will continue to be a reliable partner for businesses looking to improve their testing skills.

Having NI technology at their disposal gives Tech180 access to a multitude of useful tools and features that help them expedite development times, increase accuracy, and streamline testing processes. This increased productivity spurs innovation and expands the realm of what is practical in aerospace testing, providing real benefits to Tech180 and its clients.

Key Benefits and Innovations: NI Technology in Launch Vehicle Testing

With NI, aerospace engineers can collect exact data in real time to ensure that every part of the launch vehicle is properly analyzed by using sophisticated data collecting and control systems. This increased precision improves safety and gives users the confidence they need in the vehicle’s abilities. Specific hardware tools, such as data acquisition devices, modular instruments, and real-time controllers, are used to gather and analyze data during testing phases. In addition, NI’s software platforms like LabVIEW and TestStand, allow engineers to create custom test sequences, automate test procedures, and effectively analyze test data.

Browse NI test equipment here

Challenges and Solutions: Integrating NI Technology in Launch Vehicle Testing

Many aerospace companies, Firefly Aerospace, and Tech180 included, rely on complex systems and processes that have been developed over years of research and development. Collaborating with NI in launch vehicle testing presents a set of unique challenges and complexities that must be addressed to ensure successful implementation. One of the primary technical challenges lies in the integration of NI solutions with existing testing infrastructure and workflows.

Firefly Aerospace and Tech180 have used a range of tactics suited to their unique needs and requirements in order to get over integration roadblocks. One example of this is performing in-depth analyses of current procedures and systems to find possible integration opportunities. They can create tailored solutions that smoothly integrate NI technology while reducing disturbance and downtime by knowing the nuances of their testing environment. Both businesses have also established investments in education and training initiatives to guarantee that their staff members know how to efficiently use NI technologies.

Throughout the integration process, Firefly Aerospace and Tech180 have gained important insights and best practices that have helped to make the use of NI technology a success. For example, the value of open lines of communication and teamwork between engineering teams, IT departments, and NI representatives is one of the most crucial aspects of a mission. Through promoting consistent communication and exchanging perspectives, teams can recognize potential obstacles beforehand and collaborate to devise efficient resolutions. Taking a phased approach to integration, beginning with smaller pilot projects before ramping up to larger implementations, is another recommended strategy that ensures a smooth transition and reduces the possibility of expensive errors by enabling iterative adjustments based on real-world feedback.

While integrating NI technology into launch vehicle testing presents its share of challenges, Firefly Aerospace and Tech180 have demonstrated that with careful planning, strategic thinking, and collaboration, these hurdles can be eliminated. By addressing technical challenges head-on, employing effective strategies, and embracing lessons learned along the way, they have successfully integrated NI solutions into their testing workflows, paving the way for safer, more efficient, and more reliable launches in the future.

Future Outlook: NI Technology and the Next Frontier of Space Exploration

It’s evident that NI’s technology will be essential to advancing launch vehicle testing and other aspects of space exploration as we look to the future. With ongoing developments in data collecting, control systems, and test automation, NI technology is expected to drive much-needed innovations in launch vehicle testing. Through the use of NI technologies, engineers will be able to achieve previously unattainable levels of precision, dependability, and testing process. Because of real-time insights obtained by NI technology, rapid iteration, and development cycles will be a more realistic expectation, which will ultimately result in safer and more successful launches.

Beyond testing, there is a wealth of opportunity for using NI technology in in-flight diagnostics and monitoring. Engineers can collect vital data during flight by outfitting launch vehicles with NI-based monitoring systems. This enables real-time analysis of performance indicators and system health. By using a proactive approach to monitoring, engineers can identify any problems or anomalies early on and take corrective action before they become serious failures. Therefore, NI technology guarantees the success of every journey into the unknown by improving the safety and dependability of space missions.

The future of space exploration depends on collaboration and innovation amongst a range of organizations, including universities, aerospace businesses, and technology suppliers. In this effort, test equipment is a crucial instrument that helps stakeholders work together, exchange ideas, and push the envelope of what is possible. Utilizing NI technology as a shared platform, the aerospace industry can come together to overcome obstacles, explore uncharted territory, and solving complications.

How Apex Waves Can Help With Your Legacy Test Equipment

Apex Waves specializes in maintaining and optimizing your existing test instruments. With our expertise, we provide customized solutions and exceptional support to connect you with the exact part you need, regardless of product life cycle status.

Request a quote today!