Radio Frequency Identification (RFID) technology has transformed the way we interact with objects and data, enabling automatic identification and data retrieval. However, the complexity of Ultra-High Frequency (UHF) technology, coupled with a multitude of standards and RF parameter measurement challenges, has led to incompatibility among RFID products and significant testing difficulties.

In this blog post, we explore an innovative solution that harnesses the power of virtual instrument technology and digital signal processing to create a game-changing Multi-Protocol UHF RFID Test Platform.

The Challenge

The world of RFID is vast, with various producers and standardization organizations launching different standards and protocols for the UHF band. Unfortunately, this diversity has resulted in compatibility issues and made testing a daunting task. The need for real-time testing and the ability to support new protocol customizations only adds to the complexity. A reliable and versatile solution is crucial to reducing testing costs and ensuring seamless interoperability among RFID products.

The Solution

Enter the Multi-Protocol UHF RFID Test Platform – a groundbreaking advancement in RFID testing. Leveraging virtual instrument technology in conjunction with digital signal processing, this platform is built on the solid foundation of software-defined radio (SDR) provided by National Instruments (NI).

With this innovative platform, real-time testing of all RFID standards becomes possible, making compatibility issues a thing of the past. Moreover, it boasts a remarkable feature – the ability to support customization of new protocols, making it future-proof and adaptable to the evolving RFID landscape.

How RFID Systems Work

Before delving into the technical aspects of the Multi-Protocol UHF RFID Test Platform, let’s briefly understand how RFID systems operate. A complete RFID system consists of a reader/writer (RW), tags, and other peripheral modules. When the RW is functioning, data to be transmitted is encoded and modulated onto carrier waves of specific frequency and sent out via the antenna, creating an electromagnetic field. For longer-distance communication, backscattering is mainly used in the UHF band to transfer energy between the RW and tags.

When a tag enters the field area of the RW, it demodulates the command signals sent by the RW, processes the data, and encodes a specific response onto the carrier waves, which are backscattered to the RW. The RW captures the response signals, processes the data, and transmits the tag’s information to a computer’s database for storage and future retrieval.

The Experiment Platform

The Multi-Protocol UHF RFID Test Platform addresses the challenges faced by traditional RFID testing systems. As RFID technology evolves and communication speed requirements increase, precise timing sequences for communication between the RW and tags have become crucial.

Moreover, the existence of various RFID protocols results in differences in modulation/demodulation parameters, encoding/decoding methods, anti-collision algorithms, command and response frame structures, and instruction sets. Conventional test systems lack the real-time frequency spectrum analysis, vector signal generation, and vector network analysis capabilities needed to handle these complexities effectively.

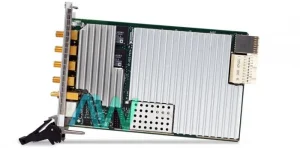

The heart of the Multi-Protocol UHF RFID Test Platform lies in its hardware components. It is built on modular devices from NI, including the PXIe-5641R RIO IF transceiver and the PXI-5610 signal generator. These components work together to create the RF signal transmitter, enabling smooth transition from a baseband signal to an RF signal.

The platform’s highlight is the use of a generic FPGA as the baseband processor, replacing conventional vector signal generators and analyzers. The FPGA’s real-time signal processing capabilities accelerate testing, while its flexibility allows prompt responses to the testing requirements of new protocols.

The Multi-Protocol UHF RFID Test Platform can be divided into two layers – the FPGA platform and the hosting computer platform. The FPGA platform handles physical transmission, receiving routes, and interfaces with the hosting computer. On the other hand, the hosting computer platform takes care of hardware control, test flow management, non-real-time signal processing, and the user interface.

The Multi-Protocol UHF RFID Test Platform has revolutionized the RFID testing landscape by providing a comprehensive, real-time, and adaptable solution. It addresses the complexities of UHF technology, compatibility issues among RFID products, and supports the testing of various protocols, including customization for future standards.

This groundbreaking platform offers RFID producers the ability to streamline testing processes, reduce costs, and ensure smooth interoperability of RFID products across the industry. With its virtual instrument technology and digital signal processing capabilities, the Multi-Protocol UHF RFID Test Platform paves the way for a more efficient and connected RFID future.

The original case study summarized in this post was published in 2013 and was authored by Chun Zhang.