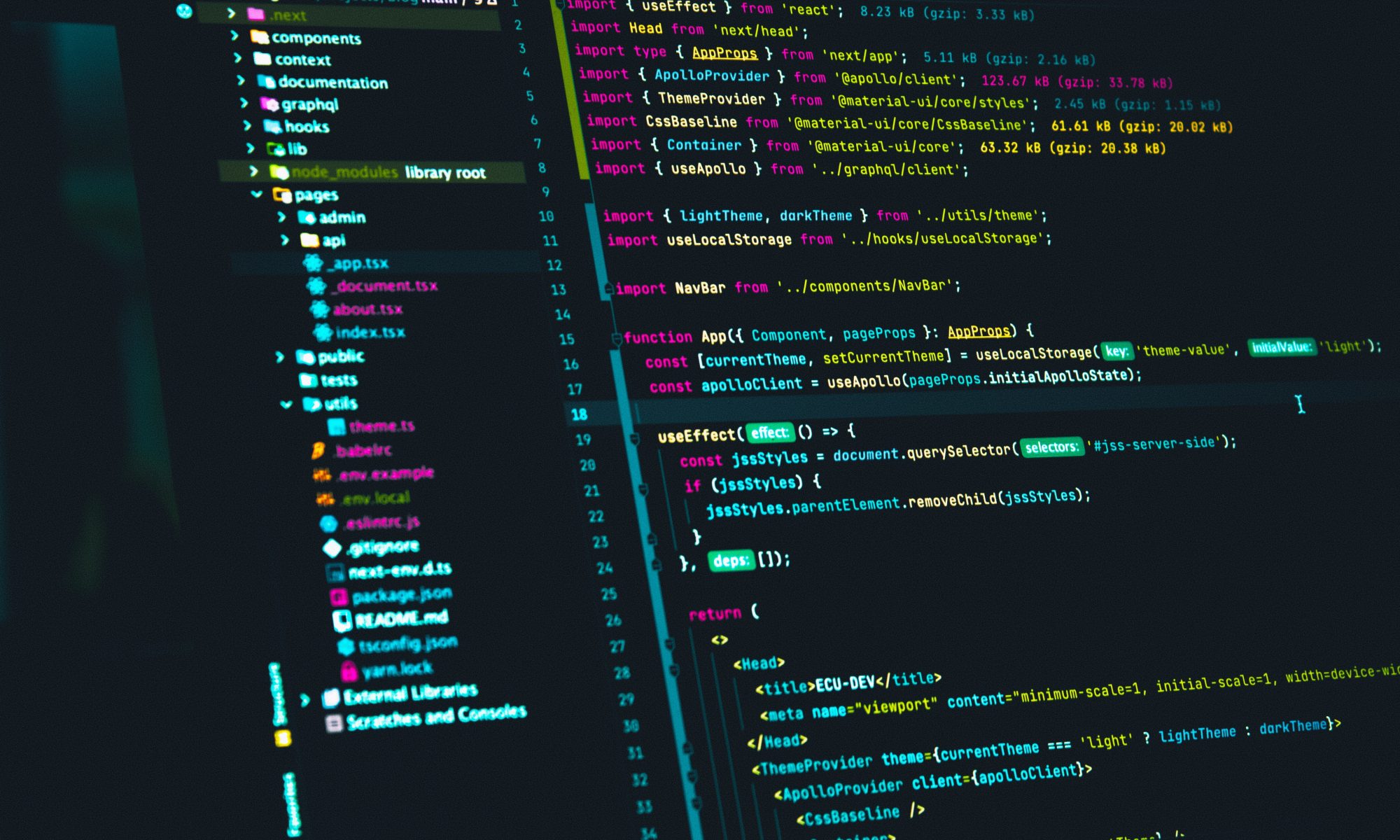

It’s no secret that software is key to creating the foundation of modern technology. With the rate at which new products and features are introduced into today’s market, the test software industry must prioritize expedient production and flexible customer delivery. How can this be accomplished? Through the standardization of test equipment! For years, the goal of testing organizations has been to achieve standardization- yet many businesses struggle to apply test standards because they can’t agree on how. However, test standardization does not have to entail a major revamp of your engineering and production testing processes. Smaller, more manageable standards, such as code or data management standards, can be implemented to address and resolve inefficiency issues.

NI and the Digital Future of Mobility

The automotive industry is rapidly expanding, with new advancements being presented every year. Breakthrough technological advances have forever transformed the industry- and brought new challenges. As a result, manufacturers are adopting technology solutions that rely on cutting-edge work ranging from cloud computing to autonomous driving. However, many businesses are still in the design and deployment stages of smart manufacturing systems.

PXI and PXIe Compatibility

The PXI and PXI Express chassis portfolio from National Instruments includes a wide range of size and performance options, as well as additional features to ease system interface and usage. The variety of options to fit specific needs is one of the reasons that the NI PXI and PXIe are industry leaders for automated testing and measurement. However, understanding the compatibility differences between the two can often lead to some confusion.

Continue reading “PXI and PXIe Compatibility”The “Why” and “When” of Test Equipment Calibration

As every test engineer planning out their Test Program Sets has probably heard at some point, keeping up with calibration is crucial. But how do you know when to get your test equipment hardware calibrated, and why exactly is it so important? Not only is it mandated by government agencies, required by quality regulations, and monitored by international standards groups- it directly impacts the efficacy of your equipment over time. While regular calibration may seem like a tedious extra step, it is clear that the benefits are well worth it. Here at Apex Waves, our stock of NI parts is fully calibrated, so each part is ready to ship to you right when you need it- at the highest quality condition available on the market.

Continue reading “The “Why” and “When” of Test Equipment Calibration”

Planning for Test Equipment Obsolescence in 2022

With each new year comes new technological advances. Technology is developing at a rapid pace, which can spell out problems for test engineers facing challenges of obsolescence within their Test Program Sets (TPSs). For test engineers in the aerospace or defense industries, where parts and products are manufactured and supported for decades, obsolescence creates unique challenges. In many cases, the TPSs the engineers work with were created in archaic software languages with little to no documentation. At Apex Waves, we understand that many of our clients have a system they’ve been using for years and don’t have the resources, budget, or time necessary to replace it. We provide the calibrated, warrantied NI parts that you need now, with a tested stock of ready-to-ship parts to help you plan for the future.

Continue reading “Planning for Test Equipment Obsolescence in 2022”

The Profound Impact of Recycling E-Waste

As the test equipment industry evolves, businesses are replacing their outdated equipment parts with the newest available models on the market. While the benefits of upgrading to the latest updates are undeniable, a large amount of e-waste is created from newly decommissioned systems. With a problem of this scale, many are turning to eco-friendly recycling initiatives for the solution. At Apex Waves, we are addressing this issue directly with our Sell Your Surplus program. It is clear that properly recycling decommissioned systems and re-using obsolete parts through this program has a strong positive impact across multiple industries.

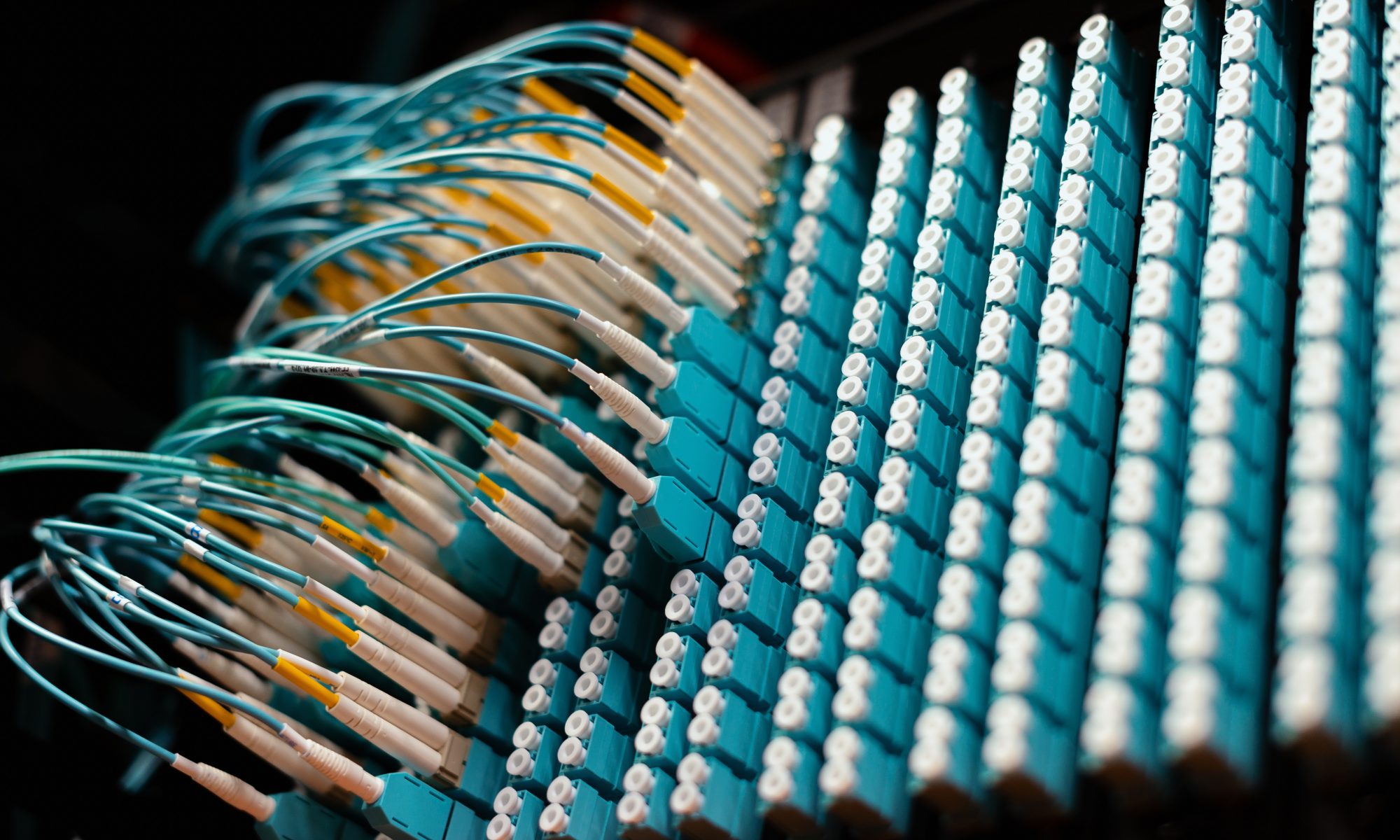

Filling in the Gaps of the ICT Supply Chain

Supply chain management is a critical part of any business, but it becomes even more invaluable in times of crisis. In February 2022, the U.S. Department of Commerce and the U.S. Department of Homeland Security published a collaborative report assessing the current state of the supply chains that are critical to the ICT industry. Their findings point to crucial gaps in this vital production process- gaps that Apex Waves is stepping up to fill. When it comes to vital test equipment components, Apex Waves maintains a large inventory of previously used, calibrated, and quality tested parts that are available and ready to ship. Because of this, important parts remain accessible for the industries and businesses that need them most.

Continue reading “Filling in the Gaps of the ICT Supply Chain”

Production Test

Nowadays, many defense programs’ duration will go beyond the typical life cycle of products, thus creating challenges for the engineers responsible for maintaining such programs. NI’s platform has made it possible for large companies like Harris Corporation to have a 74% decrease in the cost of testing and a remarkable 83% reduction in floor spaces. Since this is an issue relevant to many aerospace and defense companies, here are three best practices to refer to when dealing with production testing.

Validation: RF System-Level Validation

Synchronized operation of simultaneous, multiple, and wideband is the foundation of various new RF systems in a diverse spectrum of operations from Multiple-Input and Multiple-Output (MIMO) communications to electronic warfare systems.

Validation: Electromechanical Systems Test

Electromechanical systems are present in a wide range of complex and sophisticated vehicles such as ships, ground vehicles, aircraft, and the like. The way such standard systems work is through the software that operates on a controller. The physical components and mechanics are thus regulated by the controller, enabling the vehicles’ moving parts.

Continue reading “Validation: Electromechanical Systems Test”