When working with NI equipment for data acquisition and signal conditioning, understanding the nomenclature of accessory models can be essential. The wide range of accessories manufactured by NI are designed to both facilitate connections and enhance functionality in your testing and measurement applications.

These accessories often come with specific prefixes and suffixes in their model names, providing valuable information about their features and capabilities. In this post, we’ll explore the meanings behind these prefixes and suffixes to help you successfully navigate the different NI accessory models.

Prefixes: Unlocking the Key Features

Let’s dive into the prefixes commonly found in NI accessory models and what they signify:

BNC- (Bayonet Neill–Concelman): The connectors used by BNC accessories have BNC connectivity and are commonly used for single-ended or analog differential connections. Additionally, they include screw terminal connectors for connecting to digital and counter systems. It is intended to keep the cable’s characteristic impedance constant. Examples include: BNC-2090A, BNC-2810.

CA- (Connector Accessory): The CA prefix describes a user-configurable signal conditioning enclosure that is designed for the highest level of flexibility and user-defined I/O connections. Examples include: CA-1000

CB- (Connector Block): These unshielded screw connection blocks provide a practical option. They may be installed in customized breakout panels, or they can come with standoff feet for easy desktop usage. Examples include: CB-37FH, CB-50LP

SCB- (Shielded Connector Block): The shielded enclosure on SCB accessories houses a screw terminal connection. This architecture supports rugged and extremely low-noise signal termination. Examples include: SCB-100A, SCB-68

TB- (Terminal Block): These accessories can be attached to the front of modules without needing a cable. These compact accessories provide durable and extremely low-noise signal termination thanks to a shielded screw terminal or SMB connection. Examples include: TB-2627, TB-4300

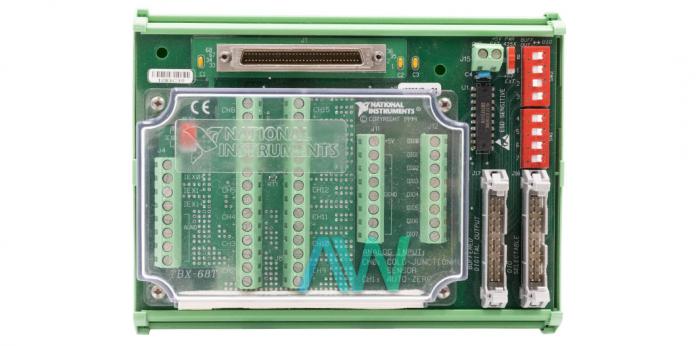

TBX- (Terminal Block): These screw terminal blocks are unshielded and are designed to be inexpensive. The mounting hardware for a standard DIN rail is included. Examples include: TBX-1303, TBX-68T

Understanding these prefixes helps you quickly identify the type and purpose of the accessory, making it easier to choose the right one for your specific application.

Suffixes: Adding Functionality and Versatility

In addition to prefixes, NI accessory models often include suffixes that convey additional information or functionality- they play a vital role in enhancing the functionality and versatility of NI accessory models! Commonly used suffixes; such as -LP for vertical-mounted connectors, -LPR for right-angle-mounted connectors, -FV for vertically mounted connectors that are perpendicular to the DIN rail, -FH for connectors that mount in line or horizontally with the DIN rail, and -F-HVD for accessories featuring higher voltage ratings and DIN-rail mounting capability, provide essential information about the physical orientation, mounting options, and voltage capabilities of each accessory.

These suffixes offer valuable insights into the physical orientation, mounting options, and voltage capabilities of the accessory, helping you select the most suitable one for your specific setup.

Why Is This Important?

Understanding the prefixes and suffixes of NI accessory models is incredibly important for test and measurement applications. These naming conventions help to simplify the selection process and ensures the seamless integration of accessories into your setup.

By decoding these prefixes and suffixes, you can swiftly determine compatibility with your existing equipment, select accessories that align with your specific testing needs, and identify cost-effective options within your budget. Moreover, these conventions indicate critical details such as signal integrity, mounting options, and voltage ratings.

This knowledge not only aids in efficient troubleshooting but also contributes to the safety of personnel and equipment in various testing environments. It ultimately streamlines inventory management and facilitates well-informed decisions, making it an essential aspect of optimizing test and measurement setups.