When the team at i-bodi Technology Ltd. reached out to Apex Waves inquiring about a PXI-1031 chassis, we were thrilled! The i-bodi team’s ability to design and develop unique test platforms is inspiring, and we were excited to see what they are working on now. In this post, we will take a closer look at one of i-bodi’s current projects, as well as how the PXI platform plays a part.

What is i-bodi?

i-bodi is a subsidiary of Crawley Creatures, an award-winning special effects company based in the United Kingdom. The company specializes in designing and developing custom prosthetics, robotics/animatronics, ultra-realistic models, and more. With a focus on applications within the entertainment industry (television, film, and museums), Crawley Creatures provides a wide range of services that require both creative and technical prowess. Among other nominations and honors, the company has received both a BAFTA and an Emmy.

Following years of success, the Crawley Creatures team was tasked in 2002 with using their knowledge of realistic robotics to assist with a different industry: research and experimental development. The project went so well that the team kept going- founding the company i-bodi to focus on this new and wide-ranging customer base. i-bodi’s success seems to come from a combination of their previous experience working on original artistic concepts and their technical expertise.

What is i-bodi Currently Working On?

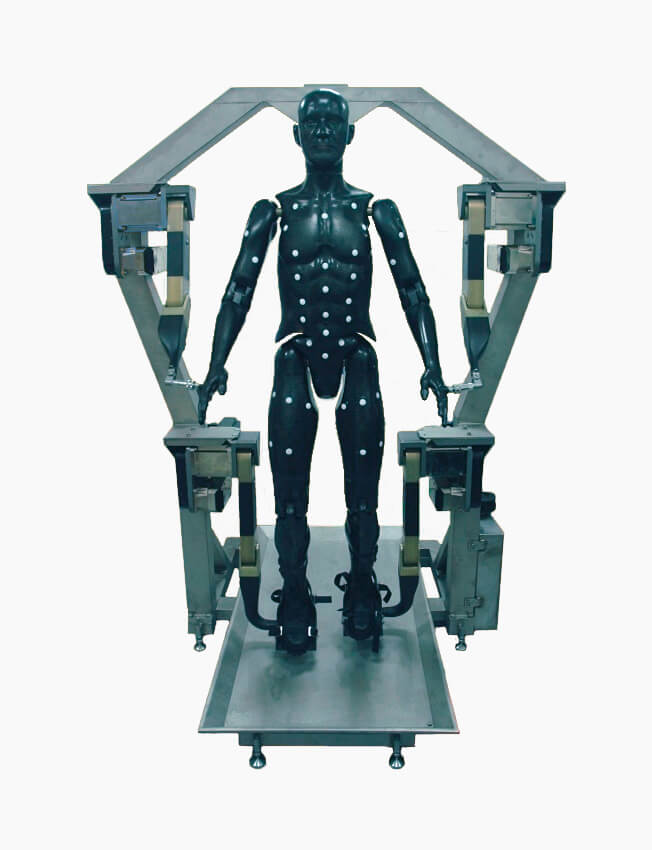

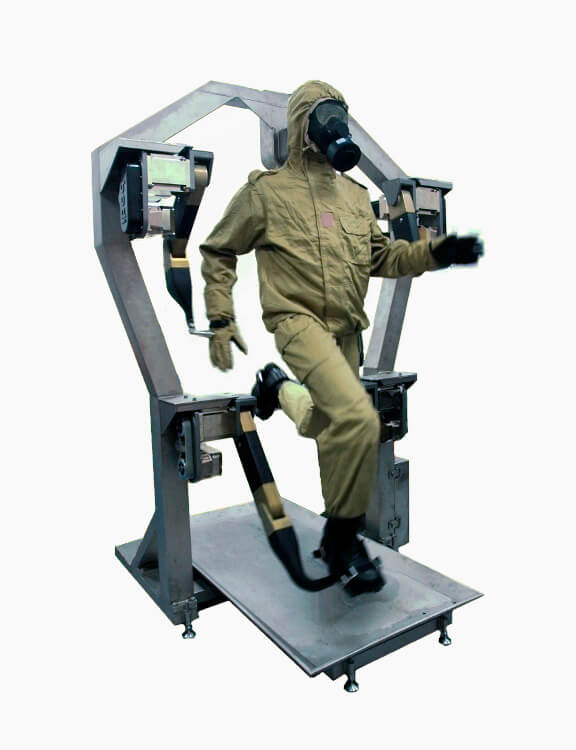

One of i-bodi’s current projects is the “Fully-Automated Anthropometrically Correct Sweating Thermo-Regulated Mannequin”, or F.A.S.T.MAN for short. This mannequin is made out of a composite of carbon materials and is designed to evaluate chemical and biological protective gear under realistic and rigorous conditions. Thanks to its sophisticated computer controls, the F.A.S.T. MAN is able to accurately replicate human physiological responses.

What makes the F.A.S.T. MAN unique?

Versatile Mobility. The drive frame of the F.A.S.T. MAN allows it to simulate a range of human actions, enabling comprehensive testing scenarios. It is able to stand, sit, kneel, shoot, climb stairs, or move into extreme positions. It can walk and run at different speeds, and the realism of these actions is enhanced by its twisting torso and swinging arm movements.

Precise Temperature Regulation. One crucial aspect of testing chemical/biological protection suits is understanding their performance under different temperature conditions. This is addressed by the F.A.S.T.MAN with a heated surface capable of individual temperature control in 11 unique zones; the head, upper arms, upper legs, pelvis, and upper and lower sections of both the front and back of the torso. The temperature range of these zones spans between 77°F and 96.8°F, ensuring precise thermo-regulation during tests.

Lifelike Sweat Production: To simulate human sweating, the F.A.S.T.MAN is equipped with a network of 62 individually controlled sweat points. These points closely replicate the response of a human body by producing up to 1 ml of sweat every minute, with a total sweat rate of up to 3.7 liters per hour. Because of this, the effects of perspiration on the protective gear can be accurately determined.

Advanced Sampling Capabilities: The F.A.S.T.MAN includes 60 passive sampler dosimeter ports within its “body”, which measure the amount of ionizing radiation that has been absorbed. These are important for evaluating the ability of the protective gear to protect from dangerous chemicals or exposure. Conveniently, additional dosimeters can be added if needed.

Robust Design: The F.A.S.T.MAN system (mannequin, frame, and trolley) is constructed using a selection of materials that have been chemically hardened to ensure durability and resistance. These materials also allow for easy and effective wash-down procedures using 10% bleach.

Why use the PXI System?

For demanding test environments such as the F.A.S.T. MAN system, the modular PXI platform provides the necessary flexibility. The PXI-1031 chassis, for example, utilizes enhanced cooling capabilities to satisfy the requirements of high-powered applications. The chassis is equipped with an auto/high temperature-controlled fan speed, 25 W of slot cooling capacity, and a 300 W general AC control supply. The PXI-1031 intakes air through the fan on its base, and cooling is aided by openings on the top, bottom, front, back, and along the right and left sides of the chassis.

To learn more about how i-bodi is innovating testing technology, visit their website at https://i-bodi.com/.